SVMtec develops and builds custom test stands for mechanical, thermal and aerodynamic processes. Our main focus is on your needs. Good communication and cooperation with our customers are the base to make the development as effective as possible.

We are also able to supply only parts of tasks such as control or data acquisition. Furthermore we can supply modifications and extensions of an existing test bench.

The scope of our activities at a glance:

• Development of concepts and methods

• Dimensioning, design and construction of test benches

• Implementation and programming of control loops

• Revision and upgrading of existing test facilities

• Integration of external hardware, such as engine control units based on the CCP protocol (CAN-bus) or others

Some examples of our realized tasks:

DNOX SCR Testing

System Test Bench for DNOX-SCR-Systems

• Examination of the overall hydraulic system as well as single components

• Testing of the electric system

• Fully automated workflow, including evaluation and documentation

DNOX-SCR Test Stand

• Simulation of thermal boundary conditions

• Cyclic tests over a long period of time

• Control of the components

• Data logging

NOX-SCR Tank Modules

• Simultaneous testing of up to 10 tank modules with various setups

• Simulation of the electrical connection to the controller

• Measurement of the electrical characteristics

• Dynamic test series with fast scan rates (50kHz)

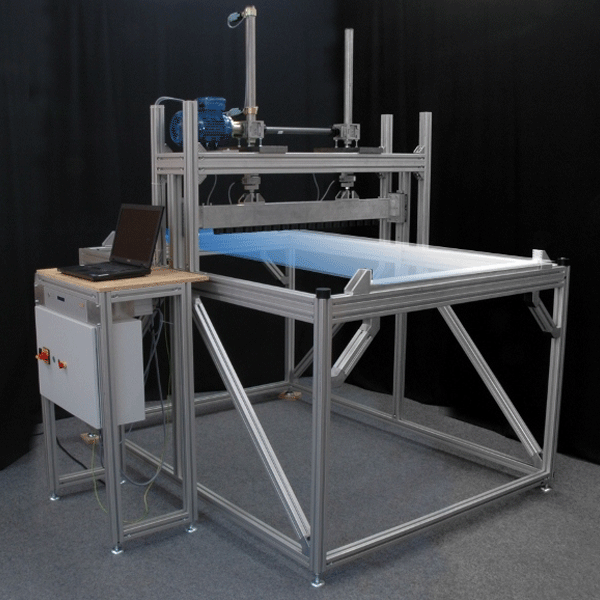

Thermo Electric Generator

Thermo Electric Modules or TE-Modules are capable of transforming heat into electric power through the effect of thermoelectricity. During the development phase, not only different combinations of materials and geometries have to be investigated, but also different mechanical and thermal loads.

• Hot side up to 600 ° C

• Cold side between 0 and 100 ° C

• Vacuum or protective gas atmosphere

• Surface pressure ranging from 0.008 to 1.6 N/mm²

• Performance measurement of TE-Modules

• Thermal cycling

Mechanic Test Stands

Test for laminated glass

• Cyclic loading

• Length or force-controlled

• Data logging

The mechanical design was provided by the customer.

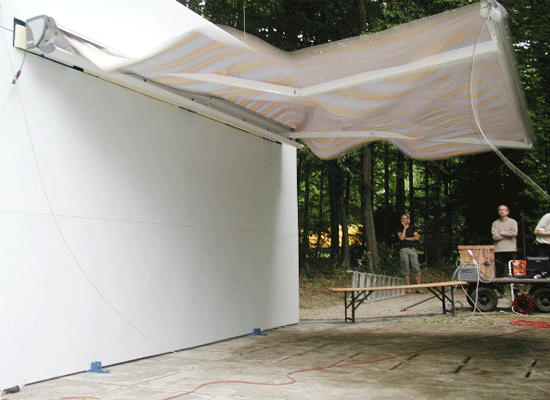

Test stand for the measurement of wind loads on awnings

3 force and 2 torque components are acquired at the awning’s wall mount.